PCI Epoxigrund Rapid

Special primer

on absorbent and non-absorbent substrates

Areas of application

- For indoor and outdoor use.

- For walls and floors.

- Primer for PCI sealings and PCI coatings on cementitious substrates, mastic asphalt screeds, ceramic tiles, synthetic resin coatings and wooden substrates.

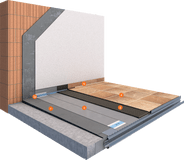

- Primer for floors in the interior before applying floor levelers/fairing coats, also when subsequently bonding parquet flooring on

- concrete floors, cement screeds, calcium sulfate screeds, magnesite screeds

- mastic asphalt screeds

- ceramic tiles and synthetic resin coatings

- wooden substrates

- substrates with residues of dispersion, reaction resin, water soluble (e.g. spent sulfite liquor adhesive) and bitumen adhesives. - Suitable as leveler and/or fairing coat when mixed with silica sand.

- As a binding agent for producing screeds, repair mortars and drain mortars based on epoxy resin.

- Suitable for the use on ships; meets the requirements of Marine Equipment Directive (MED) 96/98/EC.

Product features

- Low viscosity, reliable bond of subsequent coatings and/or sealings.

- Impermeable sealing of pores, prevents air bubbles from ascending from the substrate into the top coat.

- Moisture barrier (two coats necessary) up to a residual moisture ≤ 7 CM% in the substrate of cement screeds, on underfloor heatings up to a residual moisture ≤ 5 CM%, when used as a primer before applying floor levelers with textile and resilient flooring or parquet to be subsequently laid.

- Solvent free to TRGS 610, no damage to environment and operative due to solvent vapors, no danger of fire or explosion.

- Very low emissions, GEV-EMICODE EC 1.

- EU 2004/42/IIA(j)(550/500): < 100 g/l.

- Fast curing, subsequent work can be continued after approx. 3 ½ hours.

- As binding agent for producing screeds, repair mortars and drain mortars based on epoxy resin and able to be quickly used.

- Suitable as cast resin for the force-transmitting sealing of cracks in screed surfaces.

Colors:

transparent

Forms of delivery:

5-kg-pail/ 1-kg-can

Consumption calculator

Your Result

Quantity Required approximately

kg

corresponds

5-kg-pail

pieces

1-kg-can

pieces

Your Result

Quantity Required approximately

kg

corresponds

5-kg-pail

pieces

1-kg-can

pieces

This consumption calculation included in the program contains approximate values based on experiences which might considerably vary upwards and also downwards depending on the structure of substrate, type of tiles, different profiles on the reverse sides, type of tiling tools, work method a.o. Calculations are therefore not allowed to be based on these values. In case of larger projects we recommend to assess the consumption by making a trial surface. Applications in the combined method (buttering-floating) increase the consumption by approx. 20 to 25%. In case of powder products the data relate to the consumption of dry powder for easier calculation of the material requirement.

Building pros also use:

Matching product systems

More product systemsReferences

YOUR DIRECT CONTACT

Downloads

Technical data sheet

Declaration of performance EN 1504-2

Pavifix... Its Finished! - Systems Solutions for Gardening and Landscaping

Classification report EN 13501-1 (E/Efl)

Combined with product:

PCI Epoxigrund Rapid

MED EC Type Examination Certificate Marine Equipment Directive 2014/90/EU Item No. MED/3.18c

Combined with product:

PCI Epoxigrund Rapid

Declaration of Conformity Marine Equipment Directive 2014/90/EU Item No. MED/3.18a, MED/3.18c

Combined with product:

PCI Nanolight®, PCI Durapox® Premium Multicolor, PCI Durapox® Premium, PCI Flexmörtel® S2, PCI Nanofug® Premium, PCI Epoxigrund Rapid, PCI STL 39, PCI Durafug® NT, PCI Durapox® NT plus, PCI Durapox® NT, PCI Gisogrund® 404, PCI Epoxigrund 390, PCI Seccoral® 1K, PCI Carraflex®, PCI Carraferm®

Licensing GEV EMICODE (EC1)

Combined with product:

PCI Epoxigrund Rapid

MED EC Certificate of Conformity Marine Equipment Directive 2014/90/EU Item No MED/3.13, MED/3.18a, MED/3.18c

Combined with product:

PCI Nanolight®, PCI Durapox® Premium Multicolor, PCI Novoment® Light, PCI Durapox® Premium, PCI Flexmörtel® S2, PCI Nanofug® Premium, PCI Epoxigrund Rapid, PCI STL 39, PCI VG 2, PCI Durafug® NT, PCI Durapox® NT plus, PCI Durapox® NT, PCI Gisogrund® 404, PCI Epoxigrund 390, PCI Seccoral® 1K, PCI Periplan® Extra, PCI Novoment® Z1, PCI Novoment® M3 plus, PCI Carraflex®, PCI Carraferm®, PCI Novoment® M1 plus